Browse Tough Terrain with Confidence: Komatsu Undercarriage Parts Selection Guide

Browse Tough Terrain with Confidence: Komatsu Undercarriage Parts Selection Guide

Blog Article

Boost Performance With Undercarriage Parts and Its Utilizes

Comprehending the elaborate parts that make up the undercarriage of hefty machinery is essential for companies intending to maximize their operational efficiency. From track footwear to gears and idlers, undercarriage components play an essential duty in the efficiency and longevity of equipment. The strategic use of these elements can result in considerable enhancements in performance and price financial savings. Allow's discover how organizations can harness the power of undercarriage parts to streamline their procedures and drive success in an open market.

Relevance of Undercarriage Components

Regular maintenance and prompt substitute of undercarriage components are crucial to stop expensive downtime and make the most of efficiency. Worn-out undercarriage elements can lead to decreased grip, boosted fuel intake, and accelerated wear on other components of the equipment. By buying high-grade undercarriage components and adhering to a strict maintenance schedule, operators can maximize the efficiency of their heavy equipment and prolong its life span.

Common Kinds Of Undercarriage Components

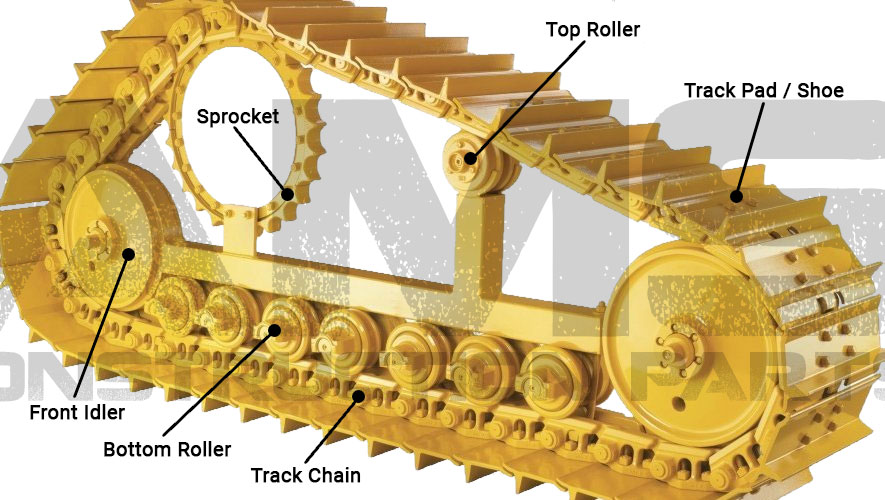

Essential components necessary for the effective operation of hefty machinery, undercarriage parts play a critical function in ensuring ideal efficiency and longevity of the devices. Some common kinds of undercarriage components consist of track chains, track shoes, rollers, idlers, sprockets, and track frameworks. Recognizing the feature and significance of these typical undercarriage parts is necessary for keeping heavy equipment in optimal working problem, reducing downtime, and optimizing efficiency on task sites.

Benefits of Routine Maintenance

Enhancing operational efficiency and lengthening equipment lifespan, regular upkeep of undercarriage parts is crucial for taking full advantage of hefty machinery performance. By sticking to an organized upkeep routine, drivers can reduce and protect against pricey malfunctions downtime. Routine inspections and servicing of undercarriage components such as tracks, rollers, sprockets, and idlers not only ensure smooth procedure however additionally add to overall security on job sites.

Enhancing Equipment Efficiency

Furthermore, picking the appropriate undercarriage components continue reading this for specific operating conditions is vital. Factors such as the kind of terrain, workload, and environmental conditions must be taken into account when choosing undercarriage elements. Utilizing top notch components that are made to hold up against the needs of the work can boost general devices performance and durability.

Additionally, keeping undercarriage parts well-lubricated and tidy is crucial for smooth procedure. Dust, debris, and lack of lubrication can cause early damage on elements, causing decreased performance and possible failures. Routine cleaning and lubrication routines can aid stop these problems and guarantee consistent tools performance.

Affordable Solutions for Companies

To optimize undercarriage parts properly and guarantee long-lasting tools Get More Info performance, services must prioritize economical solutions that align with their functional needs and budget restrictions (komatsu undercarriage parts). Investing in high-grade undercarriage parts can lead to significant cost savings in the long run by decreasing downtime, upkeep prices, and the danger of unexpected tools failures.

Another affordable technique is to source undercarriage components from trustworthy distributors that offer a balance between high quality and cost. These vendors usually provide competitive pricing, warranty options, and expedited shipping solutions, aiding organizations reduce purchase prices and decrease tools downtime. In addition, services can check out alternate undercarriage parts such as aftermarket components that fulfill sector requirements and requirements at a lower cost than OEM parts. By very carefully examining their choices and partnering with trustworthy vendors, companies can efficiently manage their undercarriage component costs without jeopardizing on performance or integrity.

Verdict

Finally, undercarriage components play a vital role in boosting equipment efficiency and efficiency. Routine upkeep of these parts is necessary to guarantee smooth procedure and avoid pricey break downs. By purchasing more tips here quality undercarriage components and implementing a positive upkeep schedule, services can improve effectiveness, lower downtime, and ultimately save money on prices. It is clear that undercarriage parts are vital components for companies aiming to boost efficiency and keep their equipment in optimal condition.

From track shoes to sprockets and idlers, undercarriage components play an essential role in the performance and longevity of equipment.The significance of undercarriage components in hefty equipment can not be overemphasized, as they are crucial components that considerably affect the general performance and durability of the devices.Important elements necessary for the effective procedure of heavy machinery, undercarriage parts play an important function in guaranteeing ideal performance and longevity of the devices.Enhancing operational efficiency and prolonging equipment life-span, normal upkeep of undercarriage parts is critical for making best use of hefty equipment performance. Additionally, businesses can discover different undercarriage parts such as aftermarket components that meet sector requirements and specs at a lower price than OEM components.

Report this page